The properties of thermosets and thermoplastics are very different, but their similarities and differences are often asked. The main difference between these two plastics is heat resistance and chemical resistance. Heat resistance is the main function of thermoset materials, while thermoplastics-more common-can only withstand a certain degree of heat. It is worth noting that plastic injection molding companies usually do thermoset or thermoplastic injection molding, but they rarely deal with both.

Below, we have broken down the differences between thermoset and thermoplastics in terms of the injection molding process, material availability, use, cost, and recyclability. Take a look:

Thermoset and thermoplastic injection molding: a comparison

Injection molding process

In thermoset injection molding, cold material is injected into an extremely hot mold to create a part. This process can solidify the part so that it can no longer melt.

In thermoplastic injection molding, the plastic material is melted and injected into a mold to make a part. Once this part has cooled, the mold opens and partly falls off.

Availability

The earliest plastic materials were thermoset, but today, thermoset injection molding is not common, except for electrical contact applications and liquid silicon. Therefore, thermoset Injection Molds machines are usually more difficult to find than thermoplastic injection molding machines.

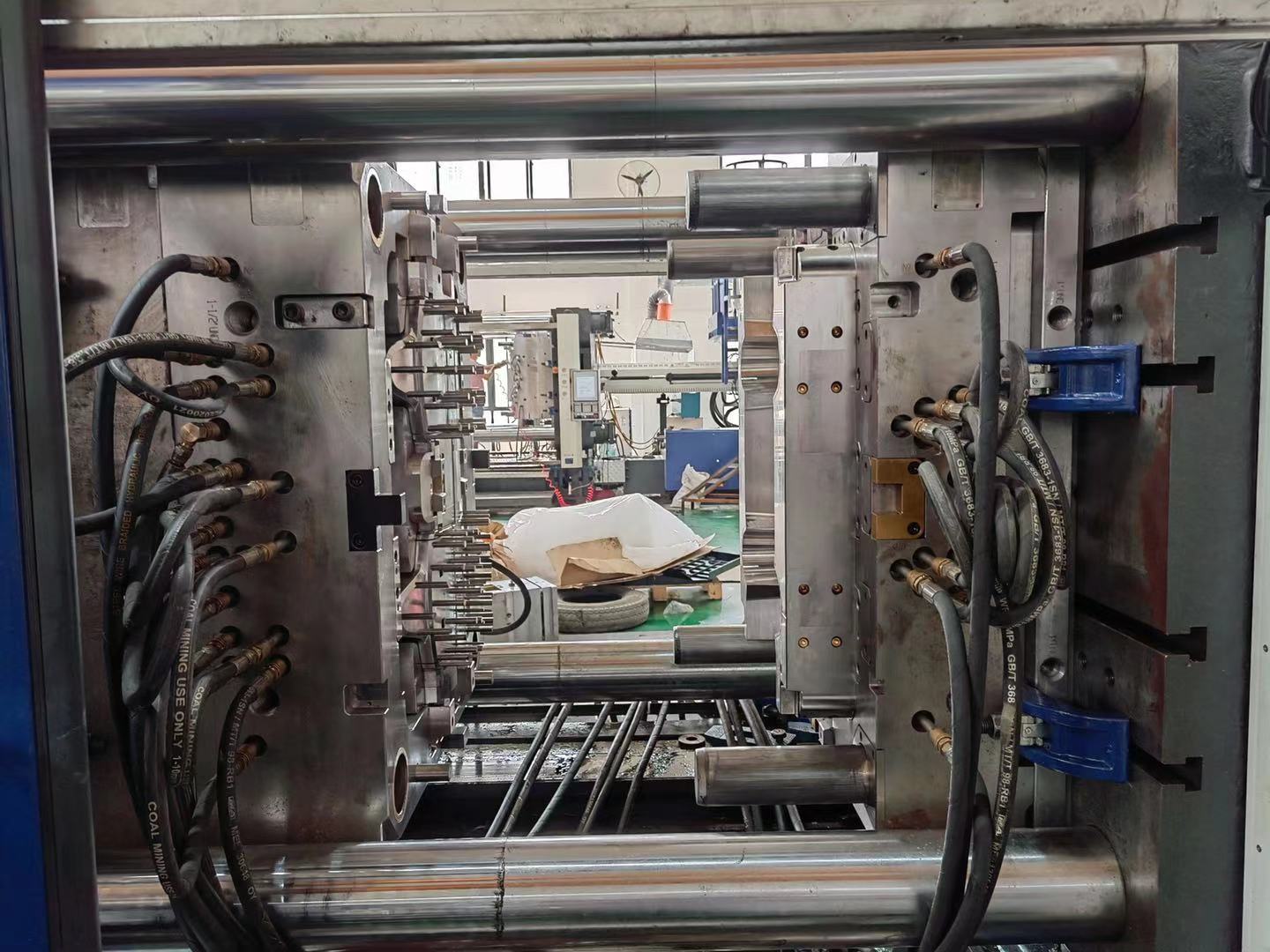

THERMOSET INJECTION MOLDS

Uses

Thermoset parts are usually used where the parts must be able to withstand high temperatures. The medical part is a good example; dental tools with silicone handles and metal parts must be able to withstand the autoclave process for disinfection and reuse, so the silicone must be thermoset. Thermosets are also used for high voltage electrical applications.

Thermoplastic parts are more likely to be used in consumer plastics, which either do not come into contact with high temperatures, such as those used in milk cans or need to withstand moderate heat. For example, some polycarbonates are resistant to high temperatures and are often used to make plastic take-out cups, but they can still deform or melt at sufficiently high temperatures.

When considering thermoset and thermoplastic parts, you also need to consider whether the parts are regularly exposed to certain chemicals. For example, if you are making a plastic case for an electrocardiograph, the material used must be resistant to any hospital-grade chemical disinfectant.

Cost

The cost difference between thermoset and thermoplastic injection molding is not black and white. The thermosetting process is usually slower—corresponding to higher cost—the material difference of thermoplastics can range from 90 cents per pound to $10 per pound, depending on performance. In other words, cost considerations should not be enough to make engineers move to one type or another—decisions should be based more on the material properties and the functions of the required components.

Recycling capacity

Thermoplastics are manufactured by melting pellets and then cooling them. This ensures that the finished part can also be remelted. This makes thermoplastics recyclable. Of course, when you melt apart, certain characteristics are different, so recycling thermoplastics does not guarantee that you get the same quality plastic parts-but it is worth noting.

On the other hand, thermosets cannot be remelted-so although thermoplastic parts can be ground and used in sandbags, their recyclability is limited.

We are Thermoset Injection Molds suppliers. Please feel free to contact us if you are interested in our products.

.jpg)