What Is Tolerance?

The tolerance stated in the plastic injection mold is an engineering requirement. In basic terms, they are allowable variants to the initial dimensions of the parts or the base dimension. As it is impossible to generate a product that purely abides by the base measurements, some leeway obtains factored into the design of items.

This margin ensures that all measurements for molded products fit the setting up demands. For example, you may wish to produce products with a size of 2.8 mm. Nevertheless, attempting to produce them might end up with some of them gauging 2.6 mm.

What tolerances do is to establish minimum as well as optimum values for the production process in a way that ensures the product fits. In this case, the reduced limit can be evaluated 0mm while the ceiling is readied to 0.3 mm. By doing this, you are assured products whose diameters range between 2.8 mm and also 3.1 mm.

The important of tolerances

Generating plastic parts for your products calls for that their measurements fit perfectly. It’s very easy to offer dimensions for the type of components you want; obtaining them to have similar measurements to your requirements is a virtually impossible venture to achieve.

The type of making procedure you go for also has a terrific bearing on the high quality of completion product. Injection molding is among the most effective processes you can experience with standards like hubbub 16901 to name a few, but it’s still unable to produce parts with the right fit.

The only escape of such a scenario where it’s impossible to get an exact suit is to leave area for some distinctions in dimension. They don’t need to be major; they simply require not interfere with the item style. This is where tolerances are available in.

What Influences Tolerance?

The kind of polymer utilized throughout the creation of your items substantially identifies whether the tolerances are within acceptable limitations. As distinct polymers obtain injected into the plastic mold, they cool as well as shrink at different prices.

Despite the fact that these shrinkage rates can be quickly represented, completion product will certainly have different tolerance ranges and also discrepancies from the acceptable varieties. The array is a dimension of the difference between the biggest as well as tiniest measurements of measurements in the created batch.

Various other aspects that figure out tolerance consist of the style of the product, the intricacy of the style along with the atmosphere the injection molded parts will certainly be running in.

Minimum/Good Tolerances for Plastic molds

The great, or rather, minimal tolerances are established by the plastic polymer you choose to use for your products. These tolerances also can be found in various forms. For one, there are dimensional, straightness/flatness, and also hole diameter tolerances. They are also divided right into business tolerances and precision tolerances, which are greater in price.

Considered that an injection-molded physical tightening is a result of the cooling, the facet of temperature level decrease is influenced by various other aspects as well. They include the thaw thermal reading, the cooling price, the thickness of the part, the dimensions of eviction, as well as much more.

Furthermore, a section of the molded product that is thicker than an additional will certainly experience even more shrinking. All these variables are since even though it is possible to forecast the behavior of the plastic polymer you wish to be molded; the material will never ever act as anticipated 100% of the time.

The polymer concerned might likewise experience warpage. This is particularly real with parts that are non-uniform as they shrink at various rates in comparison to components that have uniform wall surface thickness. These non-uniform components can happen whenever the part’s design has a concern.

The final words

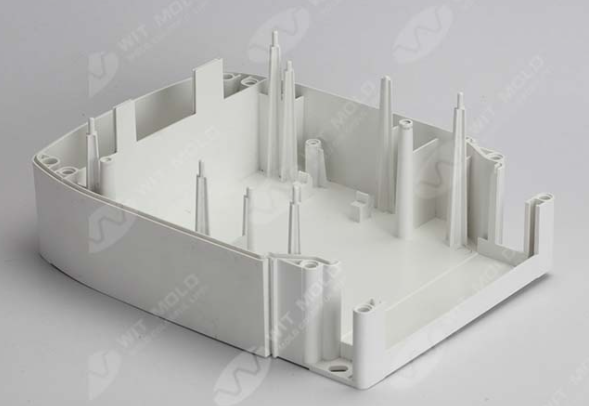

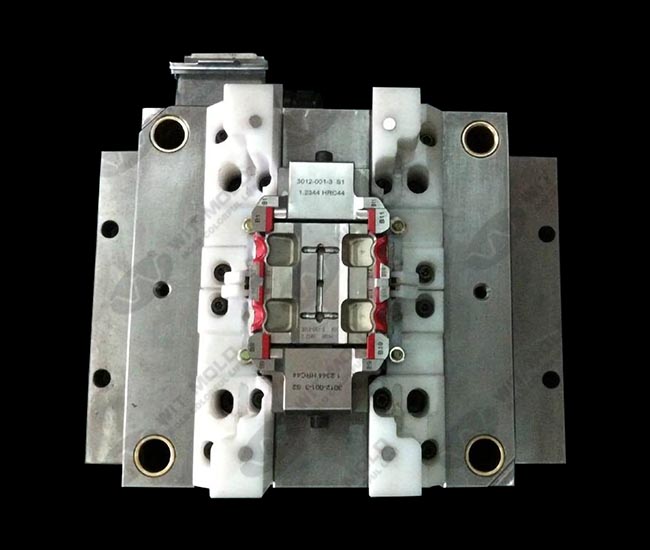

WIT MOLD has become one of the best molds in the industry because we combine the essence of the latest technology with proven traditional methods.

With an expert team composed of experienced and knowledgeable experts, we are able to complete custom orders for Custom Plastic Molds and parts that may exceed the capabilities of our competitors. We are also unremittingly committed to improving customer satisfaction, which includes providing comprehensive end-to-end quality assurance for every product we produce.