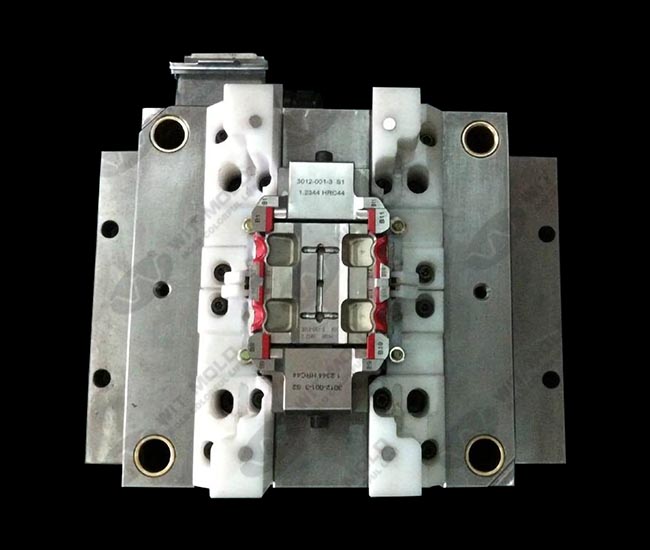

STRUCTURAL FOAM MOLDS Structural Foam Injection Moulding Structrual Foam Molds for Industrial Products

Tool features:

thick wall thickness product.

Part function: Structrual Foam molds for industrial products.

Part material: ABS+foam agent

The Structural Foam Molding Process

The process of molding parts from structural foam is very similar to the traditional method of reaction injection molding. Two components, for example polyol and isocyanate (which are combined in order to create polyurethane) are stored in liquid form in separate containers. They are mixed together to form a resin which is injected into a pre-prepared mold and cures via the means of a chemical reaction.

However, there is one important difference necessary for the creation of structural foam rather than a solid polymer. In addition to the polyol and isocyanate, an inert gas or chemical blowing agent is added to the mix during the injection process. This changes the nature of the chemical reaction which ultimately occurs.

Less polyol and isocyanate are used than in standard solid polyurethane reaction injection molding, so that the resin does not completely fill the mold. Instead, the gas or blowing agent is activated by the reaction between the two components. It expands, filling the empty space of the mold with foam. This creates the “honeycomb” texture for which the interior core of structural foam is known. Surface cells collapse when they come in contact with the walls of the mold, resulting in the creation of the solid skin which surrounds the outside of the material.

Structural Foam Molding Benefits

There are numerous benefits associated with using the foam injection molding process, these advantages include:

Utilizes less energy – This process uses less energy per pound of plastic and less raw material within the finished product.

Reduced molding costs – Part weights can be reduced by 15%, which results in lower material costs, without affecting structural integrity.

Larger product design capabilities – Smaller parts can be combined, with contrasting functions, into one part to decrease cost and increase efficiency.

Conserves raw materials – Low-pressure molding consumes less raw material than comparable methods.

Family molds run together – Due to large platen sizes, family molds can run together to create complete assemblies without the wait.

Increased dimensional stability – Low-pressure injection combined with expanding nitrogen gas results in the creation of parts with less internal stress. As a result, the foam injection molding product remains straighter and has increased dimensional stability when subjected to temperature changes and long-term weather exposure.

Increased strength to weight performance – The structural nature of the molten resin core allows for increased performance per pound of plastic.

Material variety – Lomont’s low-cost molding capabilities allow for numerous types of resins to be used.

Efficient and cost-effective – Our structural molding process offers an efficient and cost-effective way to produce advanced quality, easily repeatable parts, for your next foam injection molding project.

WIT Mold is a professional mold manufacturer in China, with 10+ years rich experience in mold making, specializing in making different types of injection molds widely used in automobiles, household electrical appliances, telephone housing molds etc.

https://witmold.com/product-item/stuctural-foal-molds/