WIT MOLD always pursue to be responsible for customers. To avoid any leaking problem at customer side, every mold needs to do water line test before shipment.

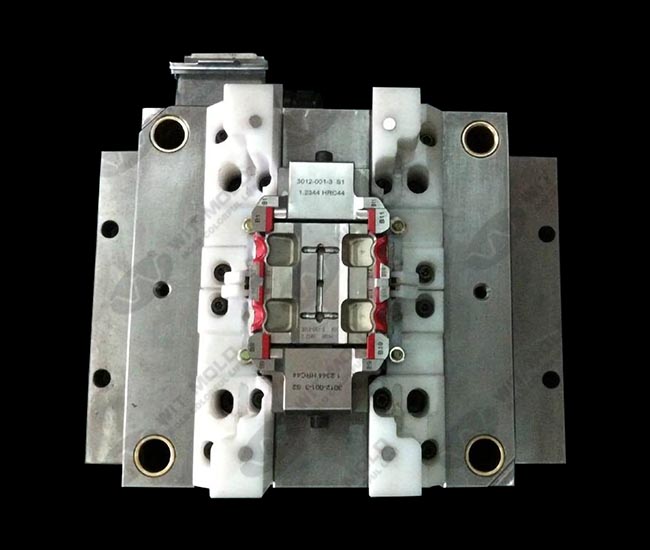

Attached is our water line test machine. The water pressure and flow must be normal value, otherwise has to review the custom paastic mold and improve until qualified. In this way, we can guarantee every mold ship to customer with good conditions.