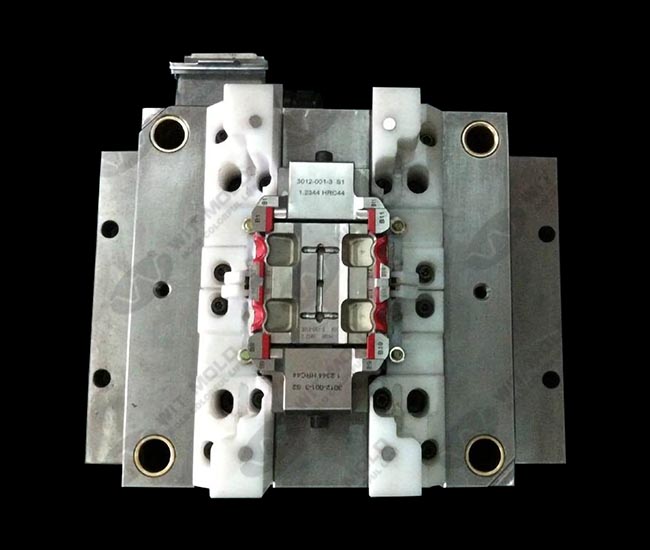

In WIT MOLD workshop, we mainly supply industrial equipment,large size mold and so on. Every work pieces will be sorted very well with the drawings and labels after finished the machining. And for the electrodes, if the customer needed, we will ship it together with the mold.

As we believe if we can do good job in every little things, also we must can do the good job in everything.

To know more: www.witmold.com