What is Two-shot Molding

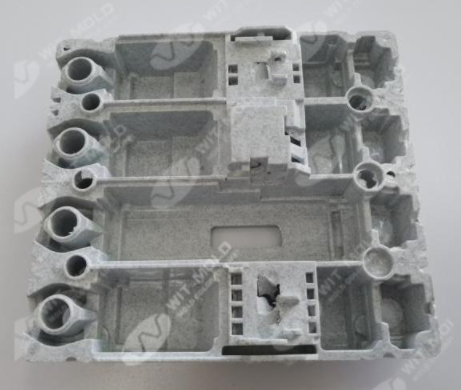

Two-shot injection molding is a multi-material injection molding process. The molded plastic part can be a combination of two different materials or a combination of different colors of the same material.

Two-shot molding can also be called 2k injection molding, double shot molding, multiple injection molding (sequential injection molding).

When Is The Use of Two-shot Molding?

ㆍProduct function requirements

For example, power switches, phone buttons, keyboard indicators, car switches, etc. Portion with an LED capable of transmitting light.

ㆍImprove the handle feeling

Some handheld products require the use of rubber in hand-held parts, which makes the hand feel more comfortable. For example, walkie-talkie housing, power tool handle, wrench, screwdriver handle, toothbrush handle, thermos, etc.

ㆍEnhance beauty

For example, some plastic parts have a logo. If you use two-shot injection molding, you don’t have to worry about it being erased.

ㆍA localized area of the product that needs to be plated

In the plastic range, only ABS and PSUsurfaces can be plated. If it is necessary to plate a part or a single side of the product, the plating area should be injected into the ABS. Areas that do not require plating are injected with other materials such as PC.

7 Suggestions for Product Design

Two-shot molding frees the designer’s creativity. However, the following factors should also be noted in the product design process.

No.1

Choose the right material. The figure below shows the compatibility of different plastics.

1 ) The core material can use low viscosity materials to reduce the injection pressure.

2) Consider from the perspective of environmental protection. The recycled material can be used as a core material.

3) Optimize the product according to the characteristics of different materials. For thick parts, the finished skin layer uses soft materials. The core material uses hard or foamed plastic to reduce weight.

No.2

If the material is not chemically compatible, the two materials can be integrated by mechanical interlocking.

No.3

Maintain proper draft angle, uniform wall thickness and smooth transition lines.

No.4

The surface of the part should be flush or slightly lower than any adjacent substrate surface.

No.5

The surface of the substrate is textured to improve the adhesion of the two materials.

No.6

The mass ratio of the two materials should not be too large. Factors such as material forming time and injection pressure should be considered.

No.7

By increasing the contact area of the two parts, the weld strength of the two materials can be enhanced.

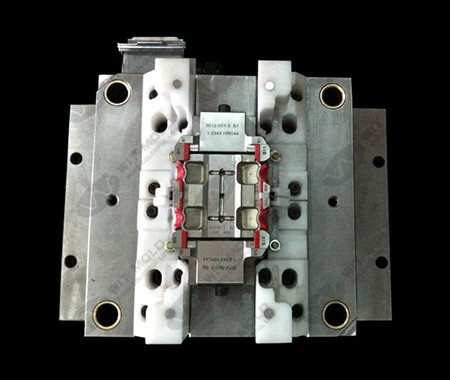

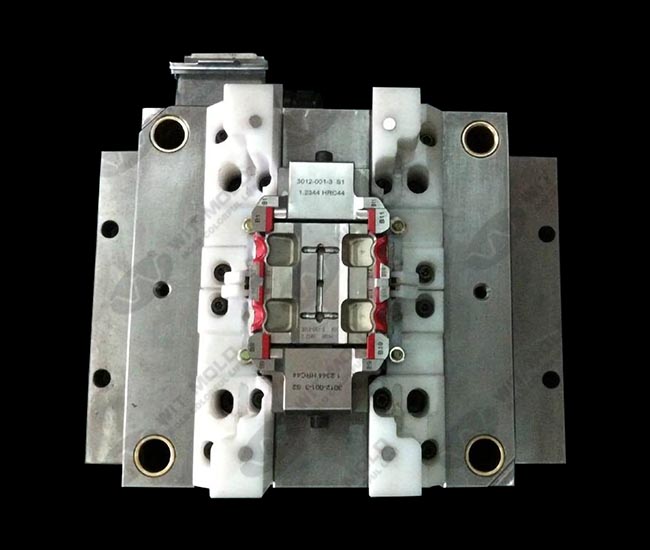

>> Check our two shot injection molds here

9 Suggestions for Two-shot Molding

No.1

The hard plastic is molded for the first time, and the soft plastic is molded for the second time. Transparent for the first time, non-transparent for the second time. The plastic with high molding temperature is molded for the first time, and the plastic with low molding temperature is used for the second molding.

No.2

Before the official production, test the mold to produce a complete product.

No.3

Identify all possible defects in the process and eliminate them before the mold is manufactured.

No.4

Consider the shrinkage of the two materials.In general, shrinkage is determined by the material that is first formed.

No.5

A second injection can only be made after the first injection has been completely completed.

No.6

Consider the molded position, to prevent damage in the process.

No.7

Allow the edge of the first injection molded part to be too large. This ensures a higher pressure during the second injection.

No.8

Ensure that the parameters of the injection unit provide the required pressure, flow rate and cooling capacity.

No.9

Ensure that the structural strength of the first molded part can withstand the injection pressure of the second molding.

6 Suggestions for Maintenance of Two-shot Mold

No.1

Check for loose or damaged fastening parts of the double shot mold. The solution is to find parts of the same specification for replacement.

No.2

After the mold has been used for a long time, the cutting edge must be cleaned and ground. After grinding, the surface of the cutting edge must be demagnetized, otherwise it will easily block the material.

No.3

Elastic parts such as springs of the two-shot mold are most susceptible to damage during use. Breakage and deformation usually occur.

No.4

The method adopted is to replace, and the specifications and model of the spring must be paid attention to during the replacement process.

No.5

Two-shotmold punch during use prone to breakage or bending. Damage to the punch and the sleeve is generally replaced with parts of the same specification. The parameters of the punch mainly include the working part size, the mounting part size, and the length size.

No.6

Check the pressure plate, top plate and other parts of the double shot mold. During maintenance, check the accessories of each part and whether there is any damage, and repair the damaged parts. Pneumatic ejector check for air leaks, and specific measures taken.

Conclusion

Two-shot molding increases the added value and productivity of the product. At the same time, plastics are becoming more and more colorful.

Correspondingly, the cost of two-shot molding is higher. Master the design points and avoid risks in advance. Avoid cost waste.

If you have any questions about two-shot injection molds, please contact us directly. Get a free quote.