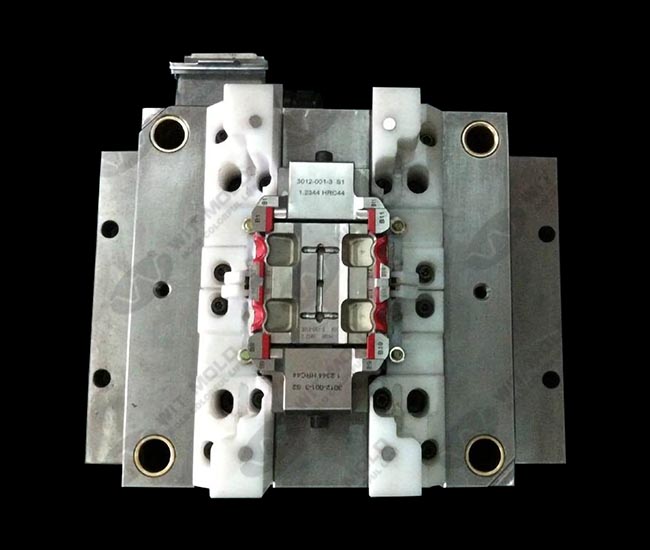

Design is the soul of mold making. In WIT MOLD, every design of production

plastic injection moulds has three processes: Prelim design, block out and final design.

This can greatly help us reduce design time and improve working efficiency. Our philosophy is to simplify the design as much as possible, so to save time and cost. For example, if a project, we can use insert solution and whole manufacturing solution at the same time. Then, we will put the insert solution as priority. Cause considering the maintenance if needed, it’s quick and easy, and also very cost-efficient.

The following picture is WIT MOLD Design flow chat: