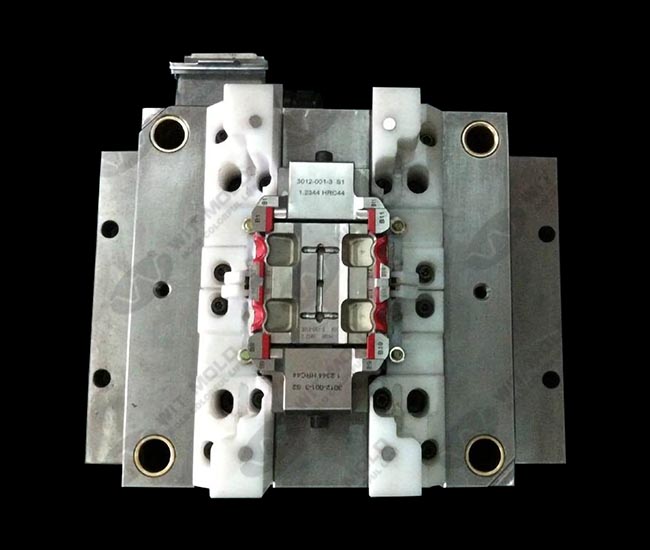

Injection mold in the production process have to assemble and test machine when the transfer mode assurance that direction and position between the male and female mold, guide parts should withstand a certain lateral force, played a role in guiding and positioning. This time we will realize the importance oriented parts, injection molds guide body parts including guide pillars and covers. So we have to analyze the problem of how to choose the orientation of parts:

1.Oriented structure of the overall design

(1) The guide member should be reasonably uniformly distributed around or close to the edge portion of the mold, the center to edge of the mold should be a sufficient distance to ensure the strength of the mold, to prevent the deformation of the press-fit guide pin and the guide sleeve.

(2) The mold according to the shape and size of a die typically requires 2-4 pillar. If, when the die punch and the die mold with the orientation requirements, the two guide posts of different diameters, or two of the same diameter, but the column-shifted position.

(3) Since the plastic parts are usually left in the male mold, so that the guide post in order to facilitate releasing the mold is usually mounted on a mother.

(4) Should guide post and guide sleeve bearing at the parting plane of flutes

(5) The axis of guide pins and bushings and guide holes should ensure parallel

(6) When be the plastic mold, should ensure that the guide member First contact, avoid public mode first into the mold cavity, damaged molding parts.

2.Design guide post

(1) A single section and stepped points

(2) The length of the guide post must be higher than the male die end face 6-8mm

(3) Part guide column head should guide cone or spherical

(4) There are riveted and fixation screws

(5) The surface should be heat treated to ensure wear resistance.

3.Guide sleeve and the guide hole

(1) Pilot hole without guide bush, directly open the template, the template is thicker, the pilot hole must be made blind holes, increased sidewall vent

(2) Guide sleeve has a sleeve type `stepped` convex Desktop

(3) In order to successfully enter the guide sleeve guide post holes, pour in the guide sleeve should have a rounded front r.