Mold saving refers to the fitting that does not reach the design accuracy when assembling the mold, and abnormalities will occur when the product is produced, and the required accuracy is not reached, and the mold saving process is required for fine adjustment.

The method of mold saving generally needs to be carried out in accordance with the standard operating steps. The operator of the mold optical polishing plant needs to strictly follow the following mold-saving operation methods to do the most basic mold-saving polishing for the mold.

- When a new mold starts to be processed, it should be cleaned with firewater (kerosene) first, and then all oil stains and unnecessary objects should be wiped off with alcohol so that when the mold is filled with an oilstone, the oilstone surface will not stick to dirt and the cutting function is lost.

- When saving molds, the bottom corners, bone pits, and dead corners of the mold should be saved first, and the protrusions and large planes should be saved later.

- Some of the modules are embedded in three to four pieces to form a module. Only rough or fire patterns are punched along the edges of the individual die openings, and then all the modules are clamped to be smooth, and the plastic parts are clamped when they are out. The position will be slightly smoother.

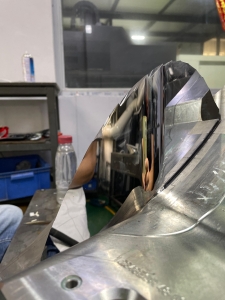

- For modules with large planes or high protrusions, be sure to use flat steel sheets and the red lead to check whether the modules are uneven or reversed after the rough grains are removed. If there is any unevenness in the finished product, it will stick mold or drag flowers.

- If the module is a flat surface and maybe a sealing position in a certain place, we can use double-sided adhesive tape to paste sandpaper on the edges that do not want to save the mold, so as to ensure that there is no place that should not be saved.

- Use copper or bamboo to press the sandpaper to save the mold. Keep in mind that the sandpaper should not be larger than the area of the tool or even the place that should not be hit by the extra sandpaper to round the mouth or change the status of unevenness.

- For processing with copper or bamboo, the shape of the tool should be similar to that of the mold, so as not to save the mold. For example, flat bamboo should be used for the plane, and small or round bamboo should be used for processing the small or round surface.

- When the mold-saving plane is next to the protruding position, sandpaper or oil stone should be struck at 15 to 30 degrees syncline to avoid a deep hole next to the protruding position.

- For example, when the crude oil stone is 150#, 180#, 220#, and other oil stones, fire water should not be added, except for light 320# and above. Manual use of copper or bamboo pieces depends on the environment at the time.

- If the module is not allowed to have fire patterns, the saver must see them clearly or use different methods to find the fire patterns and remove them. Because there are patterns after each trial of the mold. The module must be assembled and disassembled and tried again mold, it will cost a lot of man-hours and waste materials.

- Check the fire pattern method of the module. After the module is cleaned, the surface of the copper acid can be evenly coated with a brush. After about 3 to 5 minutes, the module is washed with water and dried with an air gun. After the test, the molds with no fire patterns on the surface will be darkened, and those with fire patterns on the surface will show shiny spots. Repeat the treatment with oilstone or sandpaper until there is no fire pattern, and it will be completely darkened after the copper acid test.

- You don’t need to be more serious about the blister copper male than the young copper male. As long as you omit the protruding parts of the copper male surface or the convex position, you don’t have to save the concave part. We need to find the problem to save the mold.

- If the copper male is placed on the bronze fixture of the spark machine, the four benchmark nails below must be placed on the bottom with a soft object (such as cloth, paper) to avoid unnecessary damage when the workpiece is moved, and put it on the table or on the shelf.

- Use hand or machine to hit above 400# sandpaper. Pay attention to the clean environment around the module. The sandpaper should be rubbed on the sandpaper rolls before cutting, and the slightly coarse sand particles on the sandpaper should be removed. This will reduce the sudden roughness when polishing.

- If the model saver finds an abnormality, he should report it to the supervisor. The manager should be notified when the model is completed, and should not be handed over without completion.